Introduction

Wire bonding is a integral manner in the semiconductor trade, forming the spine of electric interconnections in lots of digital units. The reliability of wire bonds without delay impacts the performance and longevity of electronic substances, making it critical to undertake perfect practices that give a boost to cord bonding reliability. This article delves wire bonding service into the intricacies of wire bonding, exploring a number of recommendations, device, and options to optimize bond nice even though minimizing failures.

What is Wire Bonding?

Wire bonding is a technique used to connect semiconductor units to their packaging or to create connections between the several dies inside of a package. This system employs first-rate wires comprised of material like gold, aluminum, copper, or silver to determine electric pathways.

How Wire Bonding Works

The wire bonding manner contains several steps:

Preparation: The bonding pads at the semiconductor die are ready. Wire Feeding: A thin wire is fed from a spool into the bonding device. Bonding: The software applies warmth, pressure, and ultrasonic vibrations (in thermosonic bonding) to create a bond among the twine and the pad. Loop Formation: The twine is then formed into a loop for extra connections. Final Bond: The moment connection is made the usage of related tactics.Types of Wire Bonding

- Ball Bonding: Involves forming a small ball at one quit of the cord until now bonding. Wedge Bonding: Uses a wedge-fashioned device for direct touch with the bonding pad. Ribbon Bonding: Employs flat ribbons in place of round wires for larger latest capacities.

Wire Bonding Techniques

Gold Wire Bonding vs Aluminum Wire Bonding

The preference between gold and aluminum twine bonding usally hinges on price and application necessities. Gold bargains first-rate conductivity but comes at a larger fee aspect in contrast to aluminum.

Copper Wire Bonding

Copper cord bonding has gained recognition by way of its shrink fee and ideal electric houses; despite the fact that, it poses demanding situations on the topic of oxidation and calls for detailed dealing with programs.

Silver Wire Bonding

Silver promises prime conductivity however can pose challenges corresponding to copper touching on oxidation throughout the time of processing.

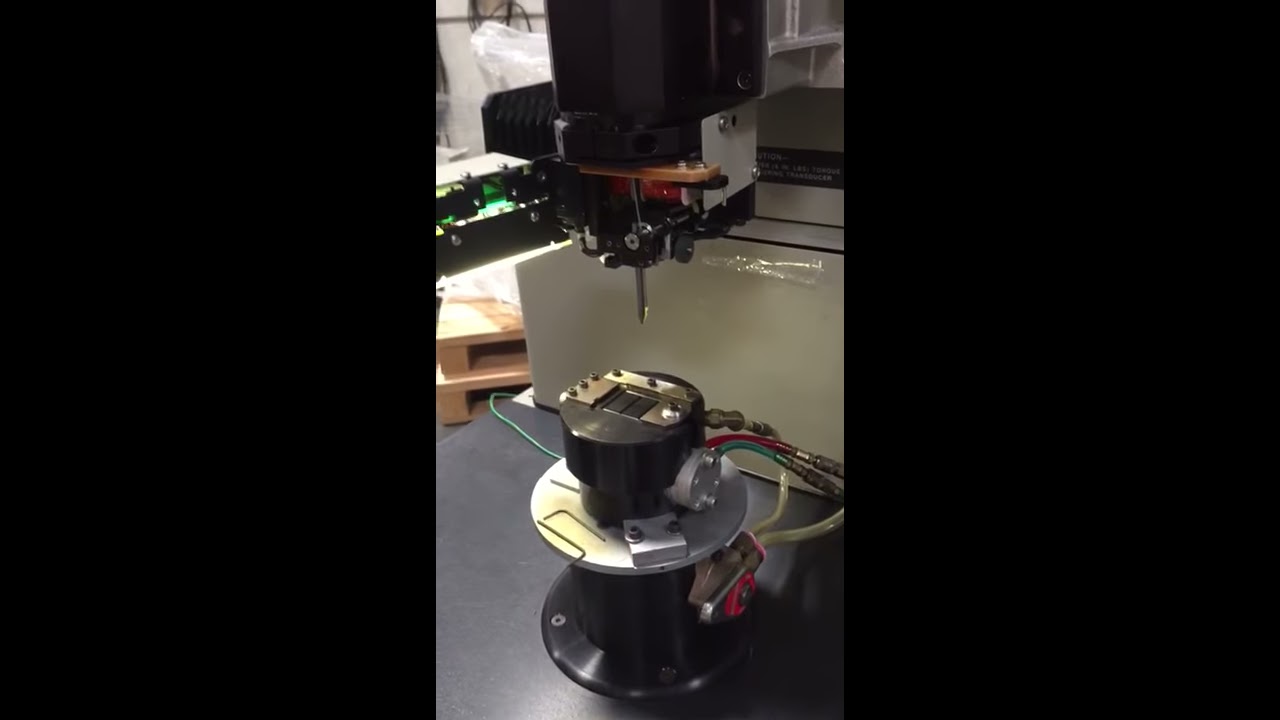

Wire Bonding Equipment Overview

Wire Bonding Machine Types

Different machines cater to precise needs:

- Manual Wire Bonders Semi-Automatic Machines Fully Automatic Systems

Programmable Wire Bonding Equipment

Programmability allows for manufacturers to customize parameters for exclusive programs most well known to stronger consistency in bond best.

Wire Bonding Applications in Electronics

From smartphones to car electronics, cord bonding performs an essential role in a considerable number of packages:

Semiconductor Packages Medical Devices LED Manufacturing Solar CellsEnhancing Reliability in Wire Bonding: Best Practices

To make sure the long-time period reliability of twine bonds, numerous practices ought to be followed:

1. Proper Material Selection

Choosing the top form of twine—gold vs aluminum or copper—can tremendously effect bond capability and longevity.

2. Environmental Controls

Maintaining managed environments reduces contamination hazards which can end in untimely screw ups.

three. Optimal Process Parameters

Parameters like temperature settings, ultrasonic pressure phases, and power would have to be calibrated safely for each one utility.

3a. Ultrasonic Power Settings

Using right kind ultrasonic persistent settings can increase bond electricity although stopping smash in the course of the activity.

3b. Pressure Calibration

Calibration guarantees consistent bond nice with the aid of making use of the best option pressure at some point of bonding operations.

4. Quality Control Procedures

Implement stringent first-rate manipulate measures consisting of visual inspections and non-damaging trying out tactics resembling X-ray inspection.

4a. Automated Inspection Techniques

Employ automatic bond inspection methods for extra professional fine assurance procedures in contrast to handbook inspections.

4b. Shear Testing Methods

Conduct shear tests on bonds most likely to evaluate their potential and discover ability things in the past they improve.

five. Continuous Training Programs

Educate operators on biggest practices because of non-stop preparation applications targeting advancements in technological know-how and methodologies related to cord bonding methods.

Wire Bond Failure Analysis

Understanding failure modes in cord bonds helps producers enforce corrective actions effectually:

1. Common Failure Modes

- Oxidation Contamination Mechanical Stress Incomplete Bonds

1a. Oxidation Issues

Oxidation can compromise bond integrity; for that reason utilizing perfect storage prerequisites is central for keeping up fabric high-quality.

1b. Cleaning Protocols Post-Bonding

Implement cleansing protocols post-bonding with the aid of gorgeous solvents or recommendations that do not spoil bonds even as quite simply putting off contaminants.

Wire Bond Testing Standards

Adhering to market requirements ensures that merchandise meet required requirements:

1. JEDEC Standards

These tips grant protocols for checking out systems making sure product reliability throughout a variety of packages along with automobile electronics or aerospace materials.

FAQs

What are the advantages of through gold over aluminum in twine bonding?

Gold delivers stronger corrosion resistance and conductivity however comes at a better charge than aluminum which won't regularly justify its use based on program standards.

What are easy defects mentioned at some stage in ball bonding?

Common defects encompass insufficient height or incomplete bonds most excellent oftentimes due loss of calibration settings or fallacious system adoption by using operators.

How can I raise my business enterprise's computerized inspection advantage?

Investing in complex imaging technologies blended with machine mastering algorithms can help make stronger defect detection charges drastically as compared traditional ways.

Why may still I habits commonplace repairs on my cord bonder?

Regular renovation guarantees most well known performance by using addressing wear-and-tear troubles early before they impression creation effectivity negatively.

Where can I discover working towards elements for progressed cord bonding techniques?

Many universities offer really good guides besides online systems featuring accomplished tutorials protecting everything from fundamentals up by means of intricate methodologies hired at the moment inside trade settings.

Is there any emerging era influencing long term tendencies during this container?

Yes! Innovations inclusive of Industry 4 .zero options integrating IoT sensors present truly-time monitoring permitting predictive analytics enhancing common manufacturing abilities extremely through the years!

Conclusion

In end, enhancing reliability in wire bonding contains meticulous cognizance to element across each thing of the strategy—from cloth variety using thorough checking out procedures aligned with commonly used requirements ensuring long-time period performance expectations are met persistently over the years! By following these pleasant practices outlined herein alongside continuous coaching tasks fostering progress inside of groups running on daily basis equipment applied throughout varied sectors globally—corporations will most likely see colossal enhancements regarding equally operational potency coupled along higher patron satisfaction ratings stemming from stronger product services being introduced subsequently!