Introduction

In the world of electronics manufacturing, the cord bonding system performs a pivotal role in starting solid electric connections between semiconductor chips and their substrates. As technological know-how advances, so does the complexity of wire bonding operations. This complexity necessitates rigorous excellent keep an eye on measures to be certain that operational potency, product reliability, and client pleasure. This article delves into the intricacies of wire aluminum wire bonding bonding technology, exploring the various approaches, kit, and programs whereas emphasizing the magnitude of great manage.

What is Wire Bonding?

Wire bonding refers to a set of approaches used to create electric connections between semiconductor instruments employing skinny wires. These connections are principal for ensuring that electronic formulation objective as meant. The twine bonding process encompasses several suggestions such as ball bonding, wedge bonding, and ribbon bonding, every with uncommon advantages tailored to express functions.

Types of Wire Bonding Techniques

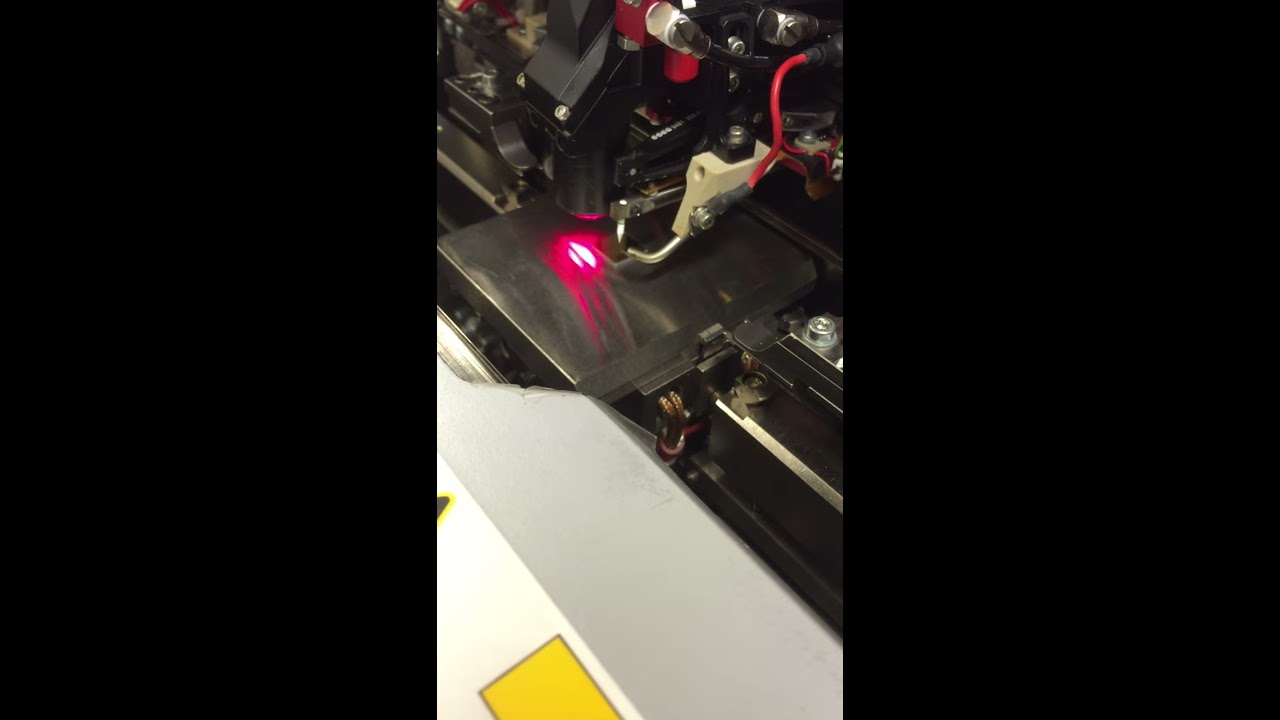

Ball Bonding- Process: Involves creating a small ball on the quit of a cord using warm and ultrasonic vigor sooner than attaching it to a bond pad. Applications: Commonly used for gold twine bonding in microelectronics.

- Process: Utilizes a wedge-formed tool that presses the wire in opposition t the substrate. Applications: Effective for aluminum and copper wires in excessive-frequency packages.

- Process: Employs flat ribbons as opposed to spherical wires to set up connections. Applications: Ideal for vigor modules as a consequence of their increased floor enviornment.

- Combines warmness and ultrasonic vigor to raise bond capability.

- Uses ultrasonic vibrations with no further warmness for specific substances.

- Enables bonding in challenging-to-reach areas within complex assemblies.

How Wire Bonding Works

The fundamental idea at the back of cord bonding comes to making use of tension and warmth (or ultrasonic electricity) to enroll in metals by means of metallurgical interconnections. It starts with opting for remarkable bonding wires—in most cases gold, aluminum, or copper—based on their conductivity and mechanical houses.

Wire Bonding Equipment Overview

Wire Bonding Machines

Modern wire bonding operations be counted heavily on really expert machines tailored for assorted styles of bonds:

- Manual Wire Bonding Machine: Designed for low-volume construction; calls for human operation. Semi-Automatic Wire Bonder: Offers partial automation to enhance productiveness even as nevertheless requiring operator input. Fully Automatic Wire Bonder: Ideal for prime-extent production; these machines can perform independently with minimal supervision.

Bonding Tools

Each mechanical device is in a position with exact tools designed for finest performance:

- Bond Capillary Tool: Used to govern and place the wire right through bonding. Wedge Bonder Tool: Essential for accomplishing certain placements in wedge bonding processes.

Implementing Quality Control Measures in Wire Bonding Operations

Quality management plays a severe position in guaranteeing that wire bonds are stable and meet enterprise principles. By implementing systematic QC measures all over the cord bonding technique, brands can drastically scale back defects and toughen product functionality.

Key Quality Control Techniques

Visual Inspection- Regular inspections will have to be performed to become aware of any visible defects resembling bond lifting or incomplete bonds.

- Techniques like X-ray inspection allow manufacturers to evaluate interior systems without damaging add-ons.

- Measures bond power with the aid of applying a strength except failure happens; supports compare bond integrity.

- Similar to tug assessments however specializes in horizontal shear forces appearing at the bond interface.

- Maintaining managed temperature and humidity tiers all over production can prevent oxidation-same screw ups.

- Regular calibration of machines guarantees constant overall performance throughout completely different batches of products.

- Keeping thorough data of every batch's parameters allows tracking lower back any defects or matters that arise submit-construction.

- Continuous practise methods for operators approximately superb practices in caliber coverage guide mitigate human errors for the time of operations.

- Establish partnerships with respectable providers who adhere to strict material quality standards reduces risks associated with inferior parts.

FAQs

FAQ 1: What are uncomplicated topics encountered in twine bonding?

Common trouble contain bond lifting, heel cracks, oxidation of bond pads, incomplete bonds, and contamination for the period of creation approaches.

FAQ 2: How do you check if a bond is strong ample?

Bond potential could be evaluated due to pull tests or shear tests the place controlled forces are implemented till failure happens; results point out no matter if bonds meet required specifications.

FAQ three: What resources are in many instances used for cord bonds?

Gold, aluminum, copper, and silver are pretty much used material simply by their fine conductivity properties; option many times relies on program specifications like thermal management or rate issues.

FAQ 4: Why is environmental manipulate precious in cord bonding?

Proper environmental controls assistance mitigate risks associated with moisture absorption and oxidation that can compromise bond integrity through the years; that is enormously principal when operating with delicate additives like MEMS or RF modules.

FAQ five: Can I operate handbook inspections properly?

Yes! However, depending solely on visual inspection may well introduce variability through human blunders; incorporating automatic inspection techniques complements accuracy enormously while delivering goal exams over timeframes critical for increased volume operations.

FAQ 6: What practising instruments are purchasable for mastering about wire bonding?

Numerous online guides exist masking every part from straightforward standards of ways wire bonding works by using improved topics like failure research; instructional papers printed by means of universities characteristically offer insights into contemporary studies trends inside this discipline too!

Conclusion

Implementing Quality Control Measures in Wire Bonding Operations isn't always simply an undertaking yet an considered necessary issue that defines fulfillment in electronic manufacturing nowadays. By concentrating on accomplished trying out methodologies blended with powerful operational protocols—along ongoing education projects—companies can beef up their production abilties even as minimizing chance elements related to poor-high-quality connections made through unreliable tricks or technology achievable at hand!

As we retain progressing in opposition t a growing number of complicated electronic designs pushing obstacles ahead—excellent insurance remains paramount! Thus investing time into information those methods will yield dividends down line—now not just financially but also recognition-wise among peers within this dynamic marketplace quarter!