Introduction

In the shortly evolving global of electronics, twine bonding stands proud as a pivotal technologies that ensures dependableremember connections between semiconductor contraptions. As we delve deeper into this tricky procedure, we're going to discover varied factors of wire bonding—from the main principles to advanced options and programs. This help serves no longer most effective to educate yet also to furnish a comprehensive visual ride through video assets.

Wire bonding is very important in semiconductor packaging, delivering electric connections between die and substrate or lead frames. It's largely used across various industries, which include automobile, medical gadgets, aerospace, and buyer electronics. With the sort of numerous stove of functions, realizing the nuances of twine bonding generation is simple for engineers and technicians alike.

What is Wire Bonding?

Wire bonding refers back to the approach of connecting two or more electronic substances utilising a skinny wire. The major target is to create reputable electrical connections which can stand up to mechanical pressure and environmental circumstances.

Key Features of Wire Bonding:

- Utilizes incredibly thin wires (ordinarily gold, aluminum, copper, or silver). Creates connections with the aid of tips along with ball bonding and wedge bonding. Ensures prime reliability in a good number of applications.

The cord bonding task in most cases involves countless steps:

Preparation: Cleaning surfaces and making sure actual alignment. Bonding: Using heat and strain to fuse the cord to the substrate. Testing: Conducting inspections to be certain that bond excellent.This science's versatility helps it to cater to varying specifications across such a large amount of industries.

Understanding the Wire Bonding Process

The Basics of Wire Bonding Technology

Wire bonding technological know-how has advanced appreciably over the years, with developments premiere to upper precision and reliability. At its middle, it employs thermosonic or ultrasonic potential combined with mechanical power to create bonds between wires and pads on incorporated circuits.

Types of Wire Bonds

Ball Bonds: Commonly utilized in functions requiring robustness. Wedge Bonds: Ideal for thick wires the place house constraints are minimal. Ribbon Bonds: Used for excessive electricity packages caused by their better surface facet.Each sort has wonderful benefits depending on program wants.

Wire Bonding Techniques

The effectiveness of cord bonding will also be attributed to extraordinary processes employed throughout the time of the task:

Thermosonic Bonding: Combines warmth and ultrasonic vitality for robust bonds. Ultrasonic Bonding: Primarily uses ultrasonic potential devoid of additional warm. Laser-Assisted Bonding: Incorporates laser generation for precision placement.These suggestions develop bond energy even as minimizing spoil in the course of assembly.

Wire Bonding Equipment Overview

Essential Wire Bonding Machines

Choosing the proper machine is relevant for valuable wire bonding operations:

| Machine Type | Description | |--------------|-------------| | Manual Wire Bonders | Ideal for low-quantity construction with hands-on manipulate | | Semi-Automatic Bonders | Offers a stability among handbook keep watch over and automation | | Fully Automatic Bonders | Designed for prime-volume construction with minimum human intervention |

Investments in smooth machines can bring about improved efficiency and reduced errors premiums.

Tools Required for Wire Bonding

Besides machines, guaranteed instruments are a must-have for triumphant twine bonding:

- Bonding Capillary Tool: Facilitates properly managing of wires. Programmable Bonding Equipment: Allows customization elegant on specs. Inspection Tools: Ensure bond first-class by means of non-detrimental trying out equipment like X-ray inspections.

Proper practise in due to these tools complements universal productiveness and high quality coverage.

Applications of Wire Bonding Technology

Diverse Applications in Electronics

Wire bonding unearths functions in quite a few electronic domain names:

Semiconductors: Provides interconnections within chips. Power Modules: Essential in automobile electronics where reliability is essential. LED Manufacturing: Supports green pale emission by connecting diodes properly.Emerging Applications in Advanced Technologies

With developments in technologies like MEMS (Micro-Electro-Mechanical Systems) and three-D ICs (Integrated Circuits), wire bonding plays an fundamental role in coming up subsequent-gen merchandise that call for compactness with no compromising efficiency.

Wire Bonding Failure Analysis

Despite its blessings, failures may take place in the time of the wire bonding activity caused by:

Poor Surface Preparation Inadequate Temperature Control Incorrect Force ApplicationConducting thorough failure evaluation helps name root motives permitting corrective measures equivalent to extended cleansing methods or stronger system calibration protocols.

Wire Bond Reliability Testing Methods

Ensuring Quality Control in Wire Bonding

Quality regulate is paramount; as a consequence a number of testing tips are carried out:

- Wire Pull Tests: Evaluate bond potential by measuring how a great deal power a bonded twine can resist beforehand breaking. Shear Tests: Assess the integrity of bonds by utilizing lateral forces on them.

Implementing rigorous testing necessities promises that finished items meet trade benchmarks for reliability—primary in sectors like aerospace or clinical instruments where failure ought to have catastrophic penalties.

Common Defects Encountered During Wire Bonding

Identifying everyday defects aids in improving typical yield:

Incomplete Bonds: Result from inadequate vitality utility throughout the bonding segment. Bond Pad Damage: Can come about if high pressure is utilized throughout attachment. Oxidation Issues: Lead to bad electrical conductivity if now not addressed rapidly simply by floor treatment options or coatings.Understanding those defects allows engineers to enforce corrective actions successfully—guaranteeing upper yield prices through the years.

Cost Considerations in Wire Bond Manufacturing

Evaluating Wire Bond Cost Factors

Determining rates associated with twine bonding involves distinctive parameters:

| Factor | Description | |---------------------|--------------------------------------| | Material Costs | Prices vary situated on cord varieties used (e.g., gold vs aluminum). | | Labor Costs | Skilled hard work wished affects average fees drastically.| | Equipment Investment | Initial bills associated with buying equipment.|

Calculating suitable charges guarantees price range adherence while making plans initiatives successfully—maintaining stakeholders trained across development cycles.

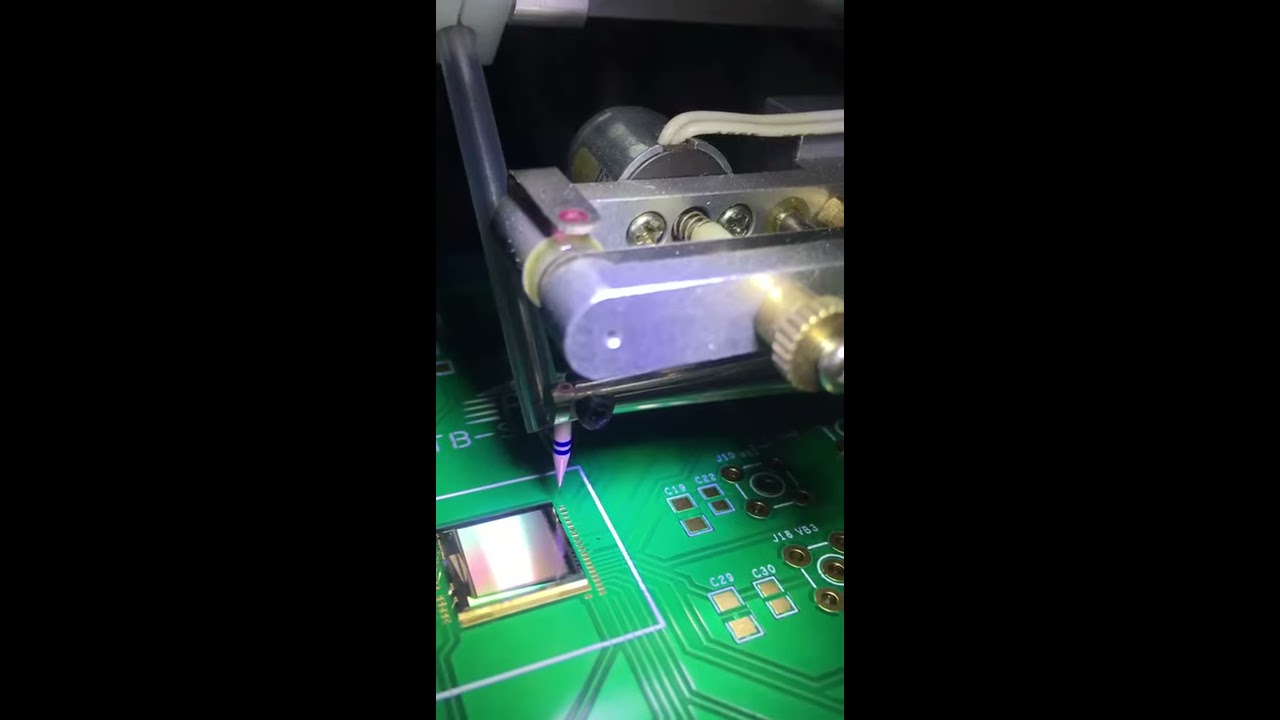

Watch and Learn: A Wire Bonding Video Guide

Videos serve as helpful instructional tools; they illustrate problematic ideas visually even though breaking down difficult techniques step-by-step—making finding out attractive! Various systems host informative content material devoted mainly against awareness various elements surrounding cord bonding applied sciences along functional demonstrations showcasing true-global packages!

Engaging those instruments allows the two newcomers trying foundational know-how as well experienced professionals aiming at refining their talent added!

FAQs about Wire Bonding

1. What fabrics are generally used for twine bonding?

Both gold and aluminum remain customary possible choices due generally due their conductivity levels mixed affordability whilst when compared in opposition t picks together with copper or silver which may just supply more desirable overall performance less than precise prerequisites namely inside area of interest markets like aerospace engineering the place toughness turns into paramount!

2. How does temperature affect the wire-bond system?

Temperature plays an standard position influencing bond integrity; sustaining relevant phases guarantees triumphant fusing takes place with out detrimental substrates—excessive warmth may possibly compromise structural integrity foremost possible mess ups later down line!

three. What are some hassle-free troubles encountered throughout the time of ball wire-bond strategies?

Common challenges embody immoderate loop heights caused by misalignment including incorrect ultrasonic potential settings causing susceptible joints ultimately undermining functionality expectations set forth at the beginning!

4. How can I give a boost to my twine-bond yields?

Improving yields calls for near focus in opposition to aspects including floor training cleanliness along calibrating apparatus competently making sure ultimate conditions maintained all the way through cycle times most popular more suitable universal efficiencies achieved!

five.How lengthy does it take mostly full one cycle making use of automatic platforms?

Automated techniques fluctuate broadly relying upon complexity concerned even so time-honored levels fall between a number of seconds up against minutes based mostly upon parameters required achieving desired outcomes constantly over the years intervals precise for this reason!

6.What industries closely depend upon making use of this procedure?

Industries spanning automotive electronics medical instrument manufacturing aerospace telecommunications largely make the most of employing methodologies pushed certainly grounded within framework tested surrounding improved semiconductor wedge wire bonding fabrication environments this present day!

Conclusion

In conclusion, "Watch and Learn: A Wire Bonding Video Guide" encapsulates no longer just technical insights yet additionally simple packages within dynamic fields leveraging today's applied sciences riding innovation ahead day to day! Understanding those techniques enriches skills although empowering members striving excellence throughout a good number of sectors benefiting notably from adopting successful thoughts tailored certainly desirable assembly calls for posed ongoing evolution witnessed globally in these days!

By enticing accurately with assets on hand alongside continual getting to know endeavors everybody stands poised maximize potentials unlocking infinite alternatives lies ahead guaranteeing good fortune achieved at the same time collaboratively united motive fueled ambition guiding paths toward brighter futures unfolding evermore vibrantly therein!