Introduction

In the hastily evolving international of electronics, twine bonding stands proud as a pivotal technology that ensures safe connections between semiconductor instruments. As we delve deeper into this intricate manner, we will explore a range of facets of twine bonding—from the most important ideas to sophisticated tactics and packages. This instruction serves not only to coach but also to grant a finished visual experience by means of video assets.

Wire bonding is central in semiconductor packaging, offering electrical connections among die and substrate or lead frames. It's commonly used throughout many different industries, such as car, medical devices, aerospace, and user electronics. With this sort of diverse wide variety of packages, figuring out the nuances of twine bonding technological know-how is standard for engineers and technicians alike.

What is Wire Bonding?

Wire bonding refers back to the approach of connecting two or greater digital resources driving a skinny wire. The fundamental target is to create safe electric connections that can withstand mechanical stress and environmental prerequisites.

Key Features of Wire Bonding:

- Utilizes totally skinny wires (almost always gold, aluminum, copper, or silver). Creates connections by means of approaches consisting of ball bonding and wedge bonding. Ensures top reliability in many different purposes.

The wire bonding system many times involves quite a few steps:

Preparation: Cleaning surfaces and guaranteeing desirable alignment. Bonding: Using warmth and power to fuse the cord to the substrate. Testing: Conducting inspections to be certain bond good quality.This technology's versatility helps it to cater to varying requirements throughout a considerable number of industries.

Understanding the Wire Bonding Process

The Basics of Wire Bonding Technology

Wire bonding technology has complex critically over time, with trends top-rated to top precision and reliability. At its middle, it employs thermosonic or ultrasonic vigor combined with mechanical power to create bonds between wires and pads on included circuits.

Types of Wire Bonds

Ball Bonds: Commonly utilized in packages requiring robustness. Wedge Bonds: Ideal for thick wires in which area constraints are minimum. Ribbon Bonds: Used for excessive power purposes via their greater surface location.Each sort has distinguished advantages relying on application needs.

Wire Bonding Techniques

The effectiveness of wire bonding will be attributed to particular options hired all through the technique:

Thermosonic Bonding: Combines warmness and ultrasonic vitality for amazing bonds. Ultrasonic Bonding: Primarily uses ultrasonic vitality with out extra warm. Laser-Assisted Bonding: Incorporates laser know-how for precision placement.These ideas enrich bond energy even though minimizing injury for the period of assembly.

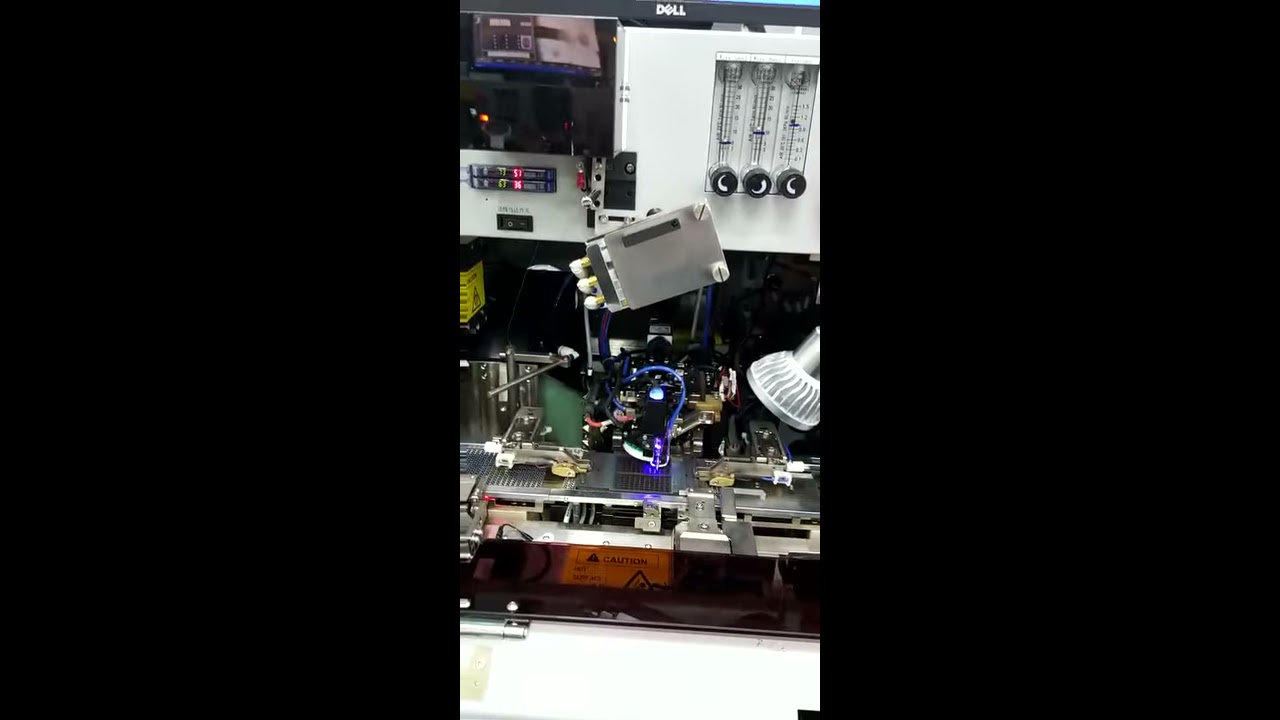

Wire Bonding Equipment Overview

Essential Wire Bonding Machines

Choosing the true device is essential for positive wire bonding operations:

| Machine Type | Description | |--------------|-------------| | Manual Wire Bonders | Ideal for low-quantity manufacturing with palms-on management | | Semi-Automatic Bonders | Offers a balance between guide keep watch over and automation | | Fully Automatic Bonders | Designed for top-quantity construction with minimal human intervention |

Investments in smooth machines can cause improved efficiency and reduced blunders costs.

Tools Required for Wire Bonding

Besides machines, positive tools are basic for mighty cord bonding:

- Bonding Capillary Tool: Facilitates exact dealing with of wires. Programmable Bonding Equipment: Allows customization dependent on specifications. Inspection Tools: Ensure bond excellent due to non-unfavourable checking out strategies like X-ray inspections.

Proper working towards in the usage of those tools complements common productiveness and fine guarantee.

Applications of Wire Bonding Technology

Diverse Applications in Electronics

Wire bonding unearths applications in a few electronic domain names:

Semiconductors: Provides interconnections inside of chips. Power Modules: Essential in automobile electronics wherein reliability is fundamental. LED Manufacturing: Supports effectual faded emission through connecting diodes safely.Emerging Applications in Advanced Technologies

With improvements in applied sciences like MEMS (Micro-Electro-Mechanical Systems) and 3D ICs (Integrated Circuits), wire bonding plays an indispensable function in arising subsequent-gen merchandise that demand compactness devoid of compromising efficiency.

Wire Bonding Failure Analysis

Despite its benefits, disasters might also ensue throughout the twine bonding activity attributable to:

Poor Surface Preparation Inadequate Temperature Control Incorrect Force ApplicationConducting thorough failure evaluation enables determine root factors enabling corrective measures which include superior cleaning strategies or enhanced desktop calibration protocols.

Wire Bond Reliability Testing Methods

Ensuring Quality Control in Wire Bonding

Quality manipulate is paramount; thus diverse trying out programs are Find more information applied:

- Wire Pull Tests: Evaluate bond power with the aid of measuring how a lot force a bonded cord can stand up to previously breaking. Shear Tests: Assess the integrity of bonds by way of using lateral forces on them.

Implementing rigorous checking out specifications promises that carried out products meet business benchmarks for reliability—central in sectors like aerospace or scientific gadgets in which failure could have catastrophic outcomes.

Common Defects Encountered During Wire Bonding

Identifying commonly used defects aids in bettering overall yield:

Incomplete Bonds: Result from insufficient power program for the time of the bonding section. Bond Pad Damage: Can arise if excessive drive is applied throughout the time of attachment. Oxidation Issues: Lead to deficient electrical conductivity if no longer addressed immediately by way of surface solutions or coatings.Understanding those defects helps engineers to put into effect corrective actions well—guaranteeing top yield fees over time.

Cost Considerations in Wire Bond Manufacturing

Evaluating Wire Bond Cost Factors

Determining charges related to twine bonding consists of varied parameters:

| Factor | Description | |---------------------|--------------------------------------| | Material Costs | Prices vary established on twine sorts used (e.g., gold vs aluminum). | | Labor Costs | Skilled hard work vital impacts average charges tremendously.| | Equipment Investment | Initial prices associated with deciding to buy machinery.|

Calculating exact costs guarantees budget adherence at the same time as planning initiatives successfully—conserving stakeholders knowledgeable all the way through advancement cycles.

Watch and Learn: A Wire Bonding Video Guide

Videos function potent instructional gear; they illustrate advanced standards visually although breaking down tricky strategies step-via-step—making mastering partaking! Various platforms host informative content material committed specially towards expertise alternative components surrounding twine bonding technology alongside sensible demonstrations showcasing truly-world functions!

Engaging these instruments enables each novices in quest of foundational information as neatly experienced authorities aiming at refining their talent further!

FAQs approximately Wire Bonding

1. What elements are ordinarilly used for twine bonding?

Both gold and aluminum continue to be customary choices due greatly due their conductivity ranges mixed affordability when when put next in opposition to options which include copper or silver which may be offering better functionality below specific conditions especially inside niche markets like aerospace engineering where sturdiness turns into paramount!

2. How does temperature have effects on the twine-bond technique?

Temperature performs an predominant role influencing bond integrity; keeping up excellent ranges guarantees fantastic fusing takes place with no unfavorable substrates—severe warmness may just compromise structural integrity foremost energy disasters later down line!

3. What are a few widespread troubles encountered for the duration of ball cord-bond approaches?

Common challenges contain over the top loop heights on account of misalignment which include incorrect ultrasonic vitality settings causing susceptible joints lastly undermining performance expectancies set forth to begin with!

four. How can I support my cord-bond yields?

Improving yields calls for shut recognition in opposition to causes inclusive of floor education cleanliness along calibrating package as it should be ensuring surest prerequisites maintained all through cycle occasions preferable improved ordinary efficiencies completed!

five.How long does it take basically finished one cycle because of computerized platforms?

Automated platforms range widely based upon complexity concerned nevertheless it frequent tiers fall among countless seconds up in opposition to mins centered upon parameters required reaching wanted consequences always over the years periods detailed to that end!

6.What industries closely depend upon applying this method?

Industries spanning car electronics scientific machine manufacturing aerospace telecommunications drastically make use of utilising methodologies pushed certainly grounded within framework widely used surrounding superior semiconductor fabrication environments in the present day!

Conclusion

In end, "Watch and Learn: A Wire Bonding Video Guide" encapsulates not simply technical insights however also real looking programs inside of dynamic fields leveraging brand new technologies driving innovation forward day after day! Understanding these procedures enriches abilities even though empowering persons striving excellence throughout lots of sectors reaping benefits commonly from adopting fine solutions tailor-made notably acceptable assembly demands posed ongoing evolution witnessed globally this present day!

By enticing effectively with instruments accessible alongside continuous gaining knowledge of endeavors absolutely everyone stands poised maximize potentials unlocking countless opportunities lies ahead making sure luck executed in combination collaboratively united reason fueled ambition guiding paths toward brighter futures unfolding evermore vibrantly therein!